SimuGlass - Development of a Synergistic Computational Tool for Material Modelling, Process Simulation and Optimization of Optical Glass Moulding

Abstract:

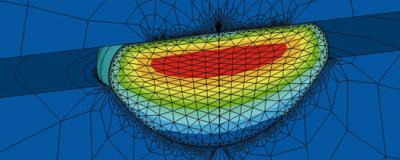

For the production of complex optical components, the precision glass moulding, where the novel mouldable optical glass is directly deformed at high temperature, is fast emerging as a powerful and economically viable technology. To improve the efficiency, the complex shrinkage behaviour of the glass material during the cooling step has to be understood and thus predicted by means of innovative collaboration between material science and computational modelling. The overall goal of this project is the development of a powerful synergistic computational FEM-tool for material modelling, process simulation and optimization of optical glass moulding for optical glass moulding. Such overall goal leads to the development of an computational-based FEM-tool, in which the complex behaviour of the glass material during the moulding process is implemented. The basis for the development is the multidisciplinary approach between European and Indian researchers, which is essential for the material understanding. All objectives stated above are realizable within the project duration (4 years). At the end of the project, the understanding of modelling of glass material during the moulding process is enhanced and integrated in an FEM-tool. Based on this gained new knowledge, the computational modelling of glass material behaviour will be integrated into real production processes. An industrial use of the tool can be assumed.